Visual Inspection

MODELS & INTEGRATION

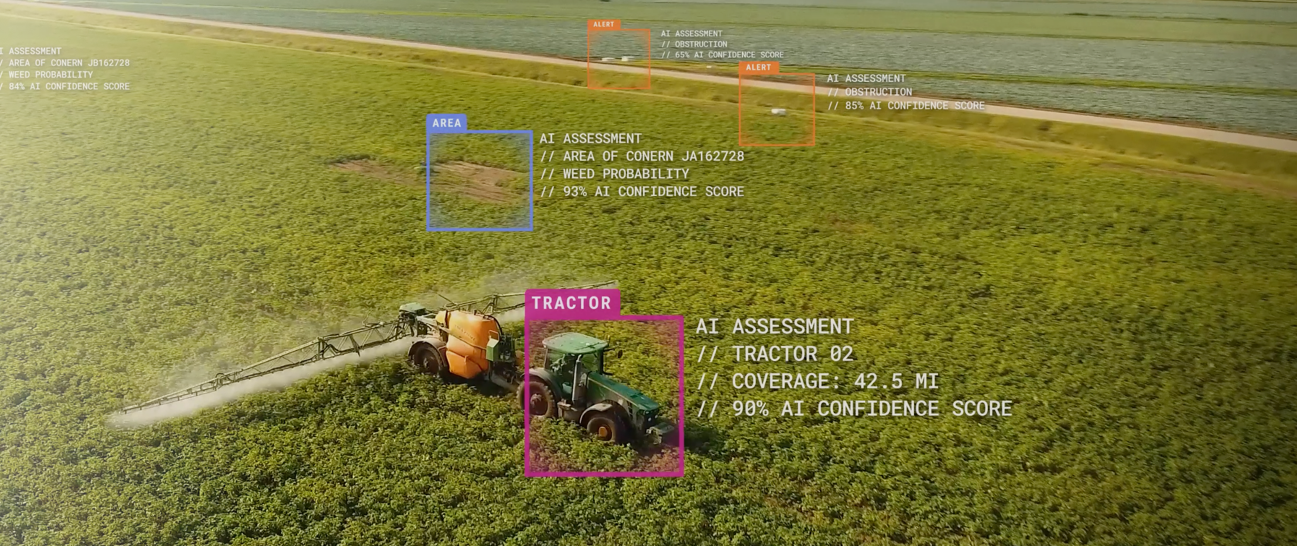

Gauge Reading Code:

CLASSES =

[“person”, “hard hat”, “vest”]

image = cv2.imread(args[“image”])

detections = net.forward ()

label = “// “,CLASSES:”, confidence *

100,”% confidence”)

[“person”, “hard hat”, “vest”]

image = cv2.imread(args[“image”])

detections = net.forward ()

label = “// “,CLASSES:”, confidence *

100,”% confidence”)

[“person”, “hard hat”, “vest”]

Reading

Clasifications: Safe

Maintenance Repairs:

Mission Reading:

Site Notifications:

Reading

Clasifications : Safe

Automated Missions:

Mission Reading:

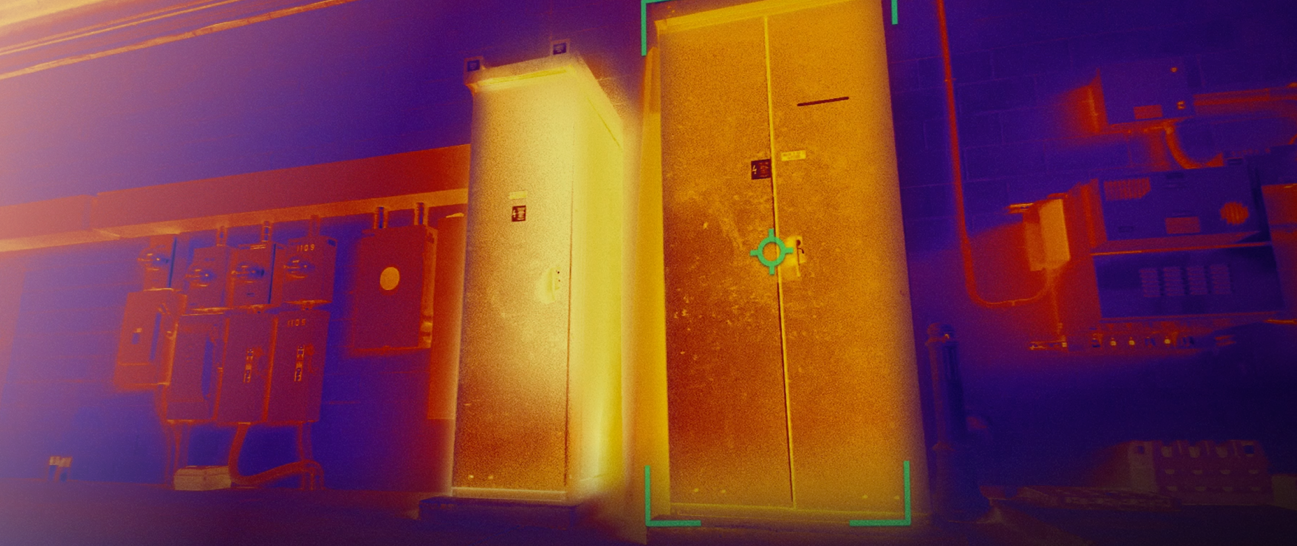

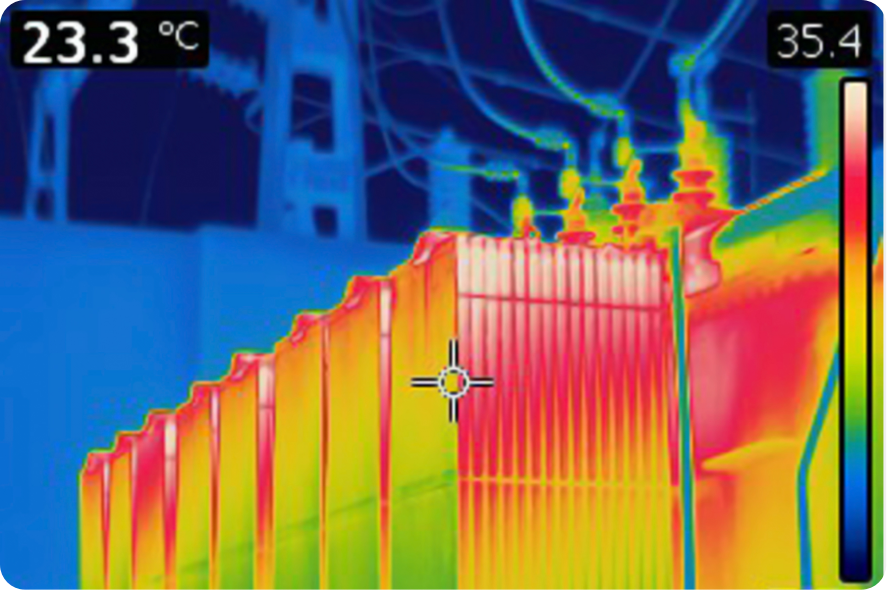

Our models work with a wide variety of visual capture platforms, ranging from CCTV and single mounts, to advanced quadruped robots and drones, from traditional RGB cameras to hyper-spectral imaging systems including thermal and X-ray.

With the right amount of data from cameras that provides quality images, our models bring the intelligence to see “beyond the pixels” and draw rich insights from the data.